|

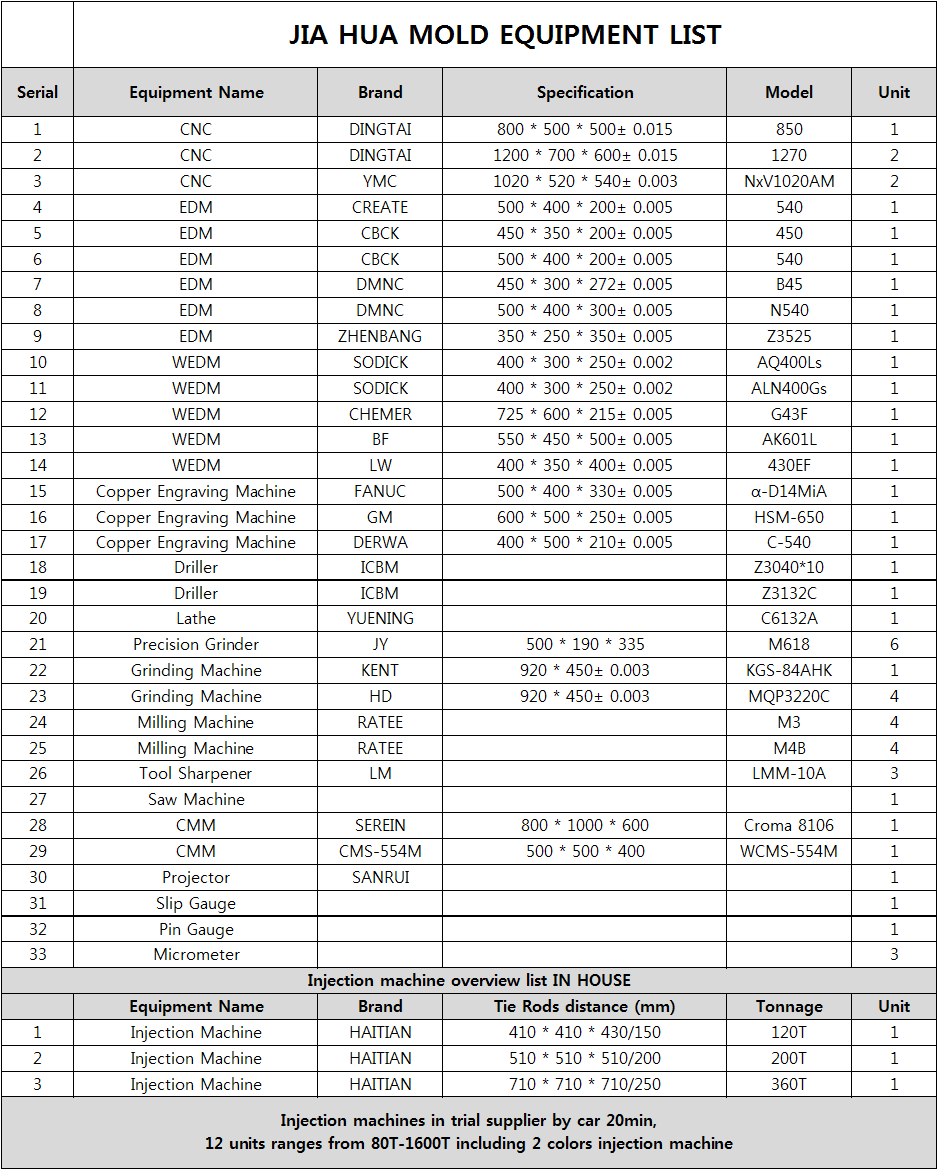

To satisfy our

customers' highest requirements, we invest on the latest technology continuously

and equipped the most advanced tooling manufacturing facilities, such as "Sodick" WEDM machines and Fanuc

High Speed CNCS, as well as a series of related auxiliary facilities etc. |

|

|

|||||||||||||||||||||||||||

|

02Mold Manufacture |

|

|

|

|

|

|

|

|

|

Our Advantage and Service

A: The cost of manufacturing injection moulds depends on various factors ranging from number of cavities, size of the parts (and therefore the mold), complexity of the part, expected mold life, surface finish and others.

B: Quotation are provided within 24H-48H receipt of RFQ.

C: Our design lead time is 2-4 days for DFM report initial 2D design, then 3-5 days for 3D design upon approval of 2D design.

D: Our common lead time from design approval to T1 sampling is 4-8 weeks, depending on mold requirements and complexity.

E: The biggest mold we have built so far is 15tons with dimension of 2.0mX1.5mX1.2m mold. Our average monthly capacitly is 25 to 30 sets of molds.

F: We have rich experiences in design and fabrication of over mould, insert mould, double colored mould and gas assisted mould.

G: We use DME, Synventive, HASCO, Mold Master and YUDO hot runner system as per customer's specification.

H: We accept files in formats such as DXF, DWG, IGES, STEP, X-T, SAT, PRT, etc.

I: We use we use IMPAX718, STAVAX136, ORVAR8407, Groditz 2344, PX88, NAK80, SKD61, H13, P20, 420, 420SS etc . as per customer's specification and mold life requirement.

J: We provide spare parts for the damageable parts of the molds.

K: Weekly progress reports with updated machining pictures are sent by email.

Mold Package

|

|

|

1、Use thin film to wrap the whole injection mould

|

2、Then put mould into a vacuum bag

|

|

|

|

3、After the mold is put into a wooden box

|

4、Finally use steel belt to solid the wooden case

|

03Parts Production

WhatsApp

WhatsApp

WeChat

WeChat